Production

Production

Stock of prepared menu items which are prepared in advance( before customer places an order )can be tracked from Production. For example let's say, each day a restaurant prepares 50 pieces of Gulab Jamun, and to make 50 pieces of Gulab Jamun, say, the restaurant requires 5 kg Maida and 10 kg Sugar. The raw materials (and their quantity) required to prepare the menu item are defined as Bill of Materials (BOM) and the stock of the menu item (Gulab Jamun) is tracked from Production.

Production can be managed in the following two ways in Just Billing Windows Pro application:

- Create BOM from back office

- Create BOM from JB Windows

Note: Bill of Materials can only be specified Make products (Procurement Method = Make). To create a BOM with the raw materials, stock for raw materials = more than 0 or as required.

1. Create BOM from back office

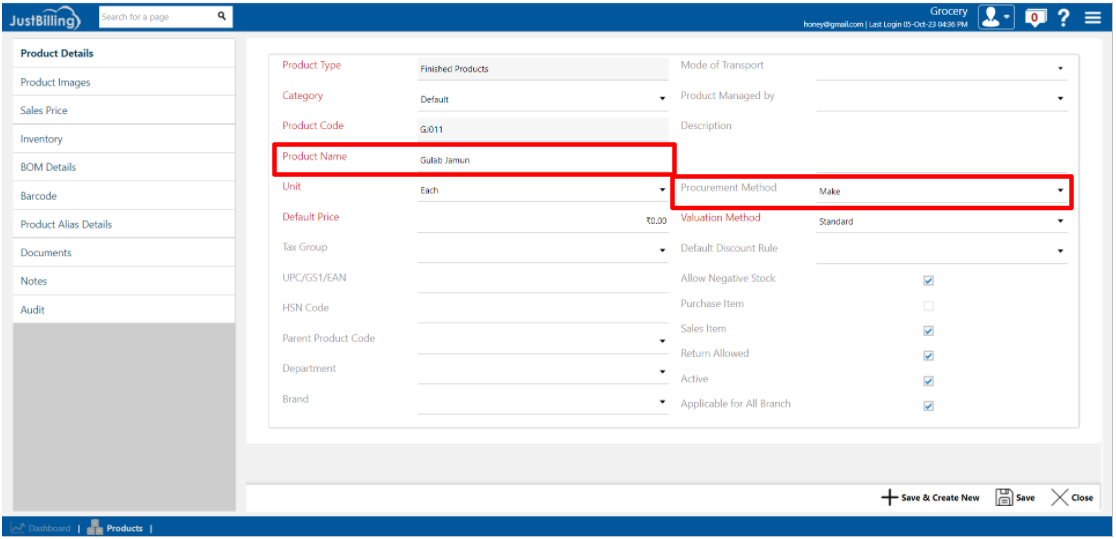

- Log into Back Office and from Menu > Back Office Management > Masters > Product Management > Products page, and edit the make product Gulab Jamun.

- Verify that the Procurement Method for this product is marked as Make and the branch (Branch here corresponds to branch name which prepares the item).

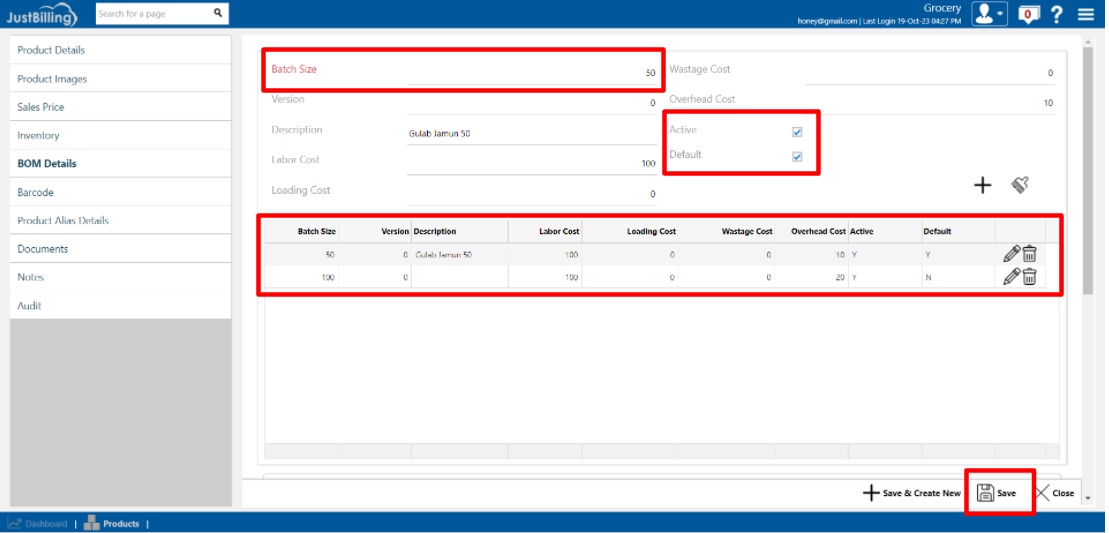

- Under Bill of Material, specify a Batch Size = 50 and set Active = Y.

NOTE: Multiple BOM can be added for the same product. In case of multiple BOM, select a Default BOM.

- Under Raw Materials select the raw material name and specify quantity, and (+) add the line.

- Save the details.

The above screen shot indicates that in order to prepare 50 pieces of Gulab Jamun, raw materials (BOM) required are 5 kg Maida and 10 kg Sugar.

Now log into the JB windows application.

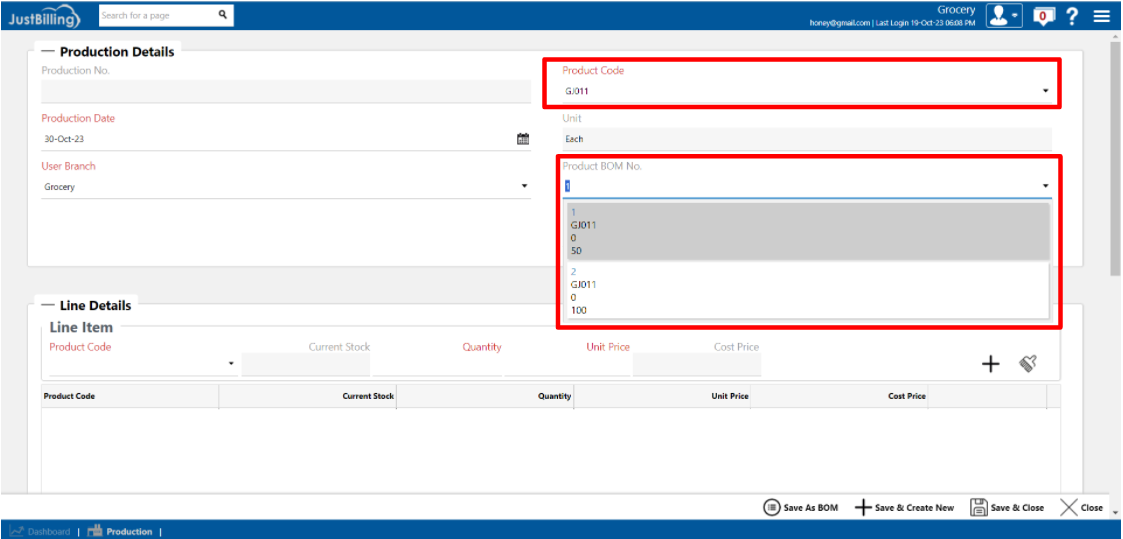

- From Menu > Transactions > Production page, select the product against which you had defined BOM from the back office - Gulab Jamun. Then select BOM number from the drop down.

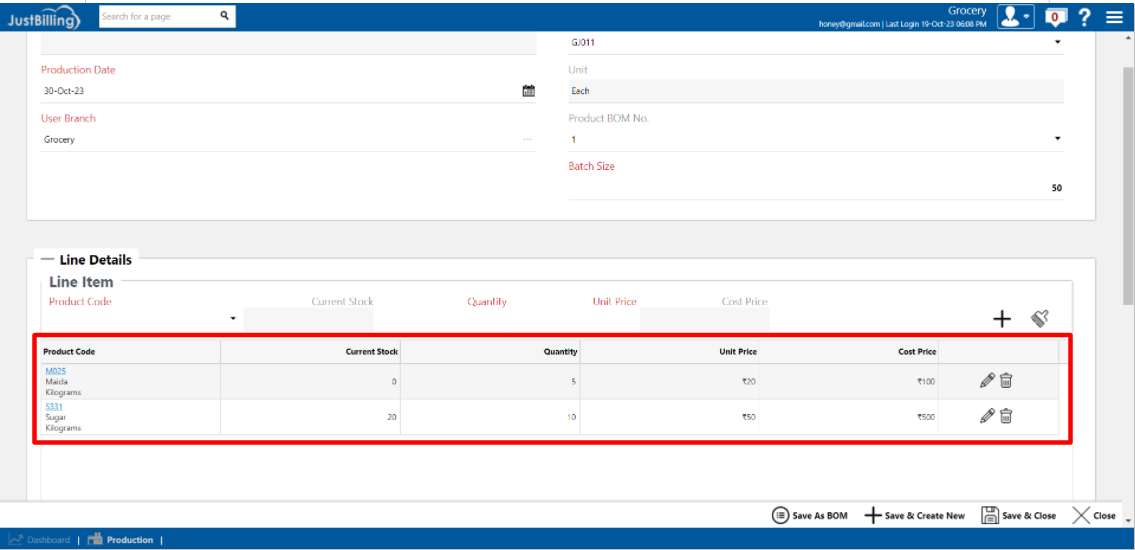

On selecting the BOM number, the Quantity of the item to be prepared, raw materials required to prepare the item, material cost and unit price will automatically get populated fro the BOM (as shown in the below screen-shot).

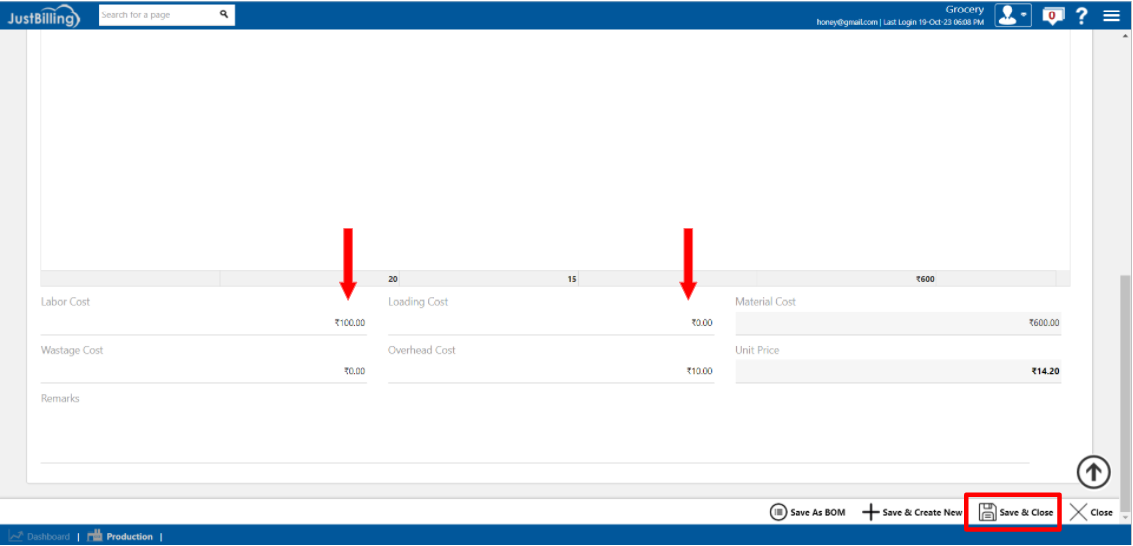

Note: When you enter the Quantity for raw materials, application automatically calculates its cost price. If you want to add additional costs such as the labor cost, overhead cost, loading cost and wastage cost, you can do so manually and Save the record. The unit cost of production in this case will be calculated by considering the Material Cost + Additional Cost (Labor/Overhead/Loading/Wastage).

2. Create BOM from JB Windows

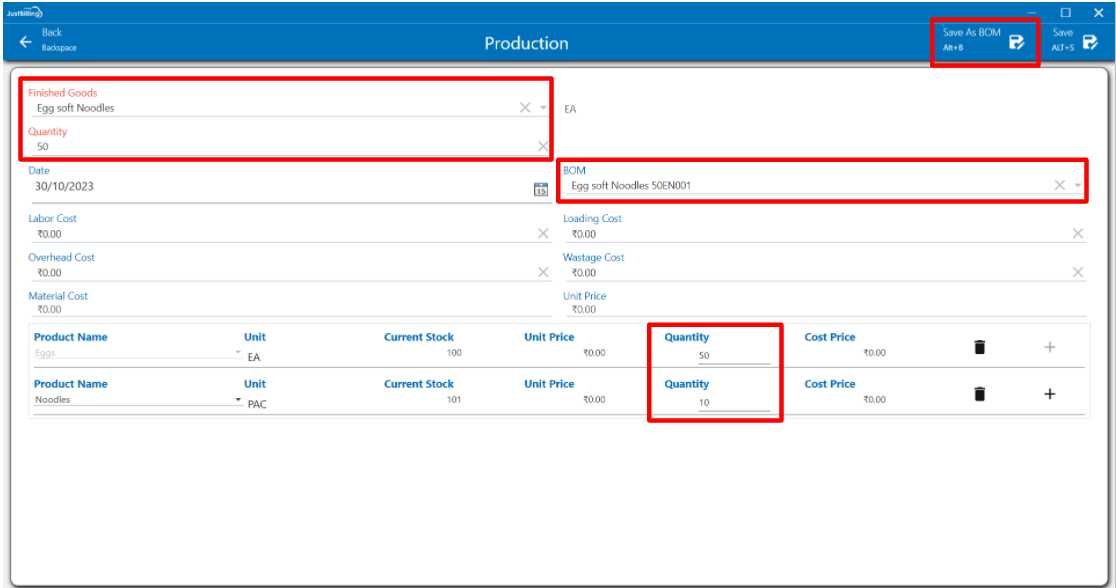

a) From Menu > Transactions > Production page, in the Finished Goods field, select the make product name against which you want to define a BOM. In this example we have selected Egg Soft Noodles.

Note: Make products are those products whose Procurement Method = Make.

b) Enter the Quantity that is prepared in advance.

c) Under Product Name field, select the raw material name that you want track for preparing the item.

d) Enter the raw material Quantity required to prepare the make product .

Note: Repeat steps - c & d for all raw materials that you want to track for making this product.

e) Save as BOM.

Note: When you enter the Quantity for raw materials, application automatically calculates its cost price. If you want to add additional costs such as the labor cost, overhead cost, loading cost and wastage cost, you can do so manually and Save the record. The unit cost of production in this case will be calculated by considering the Material Cost + Additional Cost (Labor/Overhead/Loading/Wastage).

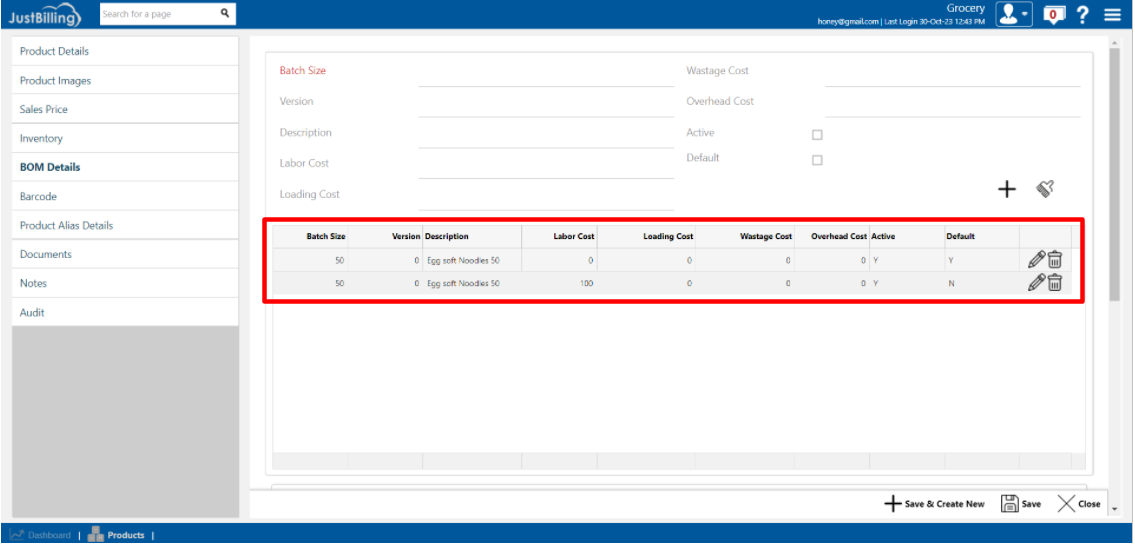

f) On saving the BOM, data from Just Billing Windows application gets synchronized with back office.

To view the BOM detail sync'd, log in to back office and navigate to the Product page.

Search for the make product name e.g Egg Soft Noodles and check the BOM from the bottom of the screen.

Note: Automatically synchronize of data from back office to application and vice versa.